The Importance of Bearings in Machinery

The Importance of Bearings in Machinery

Blog Article

Imagine a world where machines operate seamlessly, their efficiency amplified by the precision of bearings. These small components, often overlooked, play a monumental role in various industries, from automotive to aerospace. The intricacies of bearing types can be daunting, yet understanding them is crucial for optimizing machinery performance. One resource that stands out for its comprehensive offerings is Aubearing, a platform dedicated to providing a vast array of bearings tailored to meet specific needs.

The Importance of Bearings in Machinery

Bearings are essential to reducing friction between moving parts, allowing for smoother operation and longer service life. They can be found in everything from electric motors to conveyor systems. For instance, consider the automotive industry: a vehicle's lifespan is heavily influenced by the quality of its bearings. A well-designed bearing can minimize wear and tear, ultimately leading to reduced maintenance costs and improved reliability.

Diverse Bearing Types and Their Applications

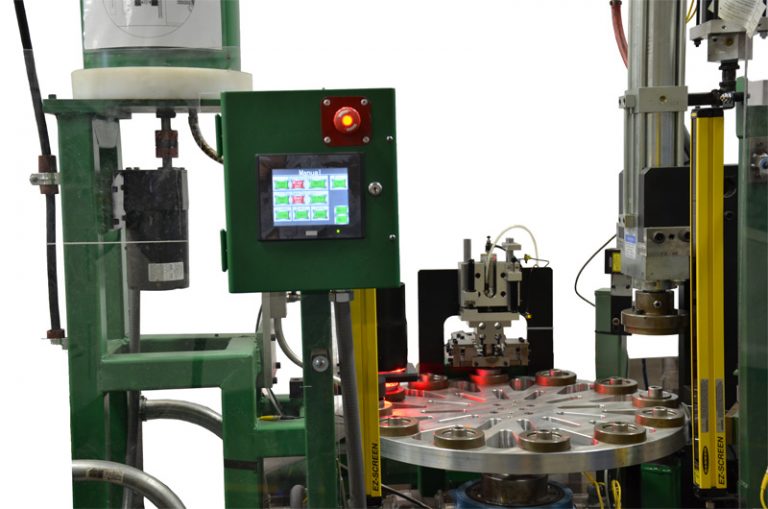

When it comes to bearings, one size does not fit all. There are numerous types, each with unique properties and applications. Ball bearings, for example, are ideal for high-speed applications and are commonly used in motors. In contrast, roller bearings excel at handling heavy loads and are prevalent in construction machinery. Understanding these differences helps engineers and technicians select the right bearing for the job, ensuring optimal performance.

For those looking to delve deeper into the world of bearings, Explore Aubearing's Bearing Collection Website. This platform offers an extensive range of information on various bearing types, helping users make informed decisions.

[IMAGE]

Choosing the Right Bearing for Your Project

Selecting the appropriate bearing involves several considerations, including load capacity, speed, and environmental factors. For instance, in a high-temperature setting, ceramic bearings might be more suitable than traditional steel bearings due to their thermal stability. Additionally, the lubrication type—whether oil or grease—can significantly influence the bearing's performance and longevity.

Maintenance and Care for Bearings

Even the highest quality bearings require maintenance to ensure they continue to perform at their best. Regular inspections should be conducted to check for signs of wear, such as unusual noises or vibrations. Proper lubrication is also critical; without it, bearings can quickly fail, leading to costly downtime. Implementing a scheduled maintenance plan can significantly extend the life of bearings and the machinery they support.

Innovations in Bearing Technology

The bearing industry is not static; it is continuously evolving. Innovations such as smart bearings equipped with sensors are becoming increasingly common. These sensors can provide real-time data on temperature, load, and vibration, allowing for predictive maintenance and reducing the likelihood of unexpected failures. Such advancements not only enhance efficiency but also contribute to a safer working environment.

Conclusion

Bearings may be small components, but their impact on machinery performance is monumental. By understanding the various types and their applications, professionals can make educated choices that lead to improved efficiency and reliability. For further resources and insights, don't forget to Explore Aubearing's Bearing Collection Website, where a wealth of information awaits to guide your bearing selections.

Report this page